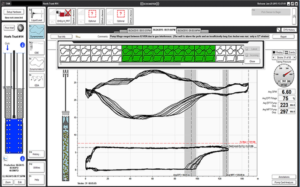

A computerized instrument for acquiring data, acoustic pressure waves are sent through Tubing/Casing (Up to 5000 Psi) with a certain velocity (depending on gas gravity…) and collected back by sensors, The RTTT is calculated, corrected and analyzed to deliver a final reptor to determine.

- actual liquid Level and down-hole parameter

- Pressure transient, Reservoir evaluation during fluid up and drow down

- Tubing integrity, pin-hole, tubing collapse, SCSSV status…

- SSD, GLV status…

FEATURES

- Fires remotely

- Designed for use with the Well Analyzer system or Model M

- Required for automatic acquisition of pressure transient data

- working pressure 1500 PSI

The Remote Fire Gas Gun utilizes a high-performance microphone with an excellent signal-to-noise ratio along.

A solenoid valve releases gas from the gas gun volume chamber into the well. The solenoid is operated automatically from the Well Analyzer system.

The Remote Fire Gas Gun is required for the automatic acquisition of pressure transient data. It is normally supplied with a 1500 PSI pressure gauge and a 1500 PSI pressure transducer.

The 5000 PSI Gas Gun is a manually operated gas gun excellent for use in gas lift, flowing, and high-pressure shut-in wells. While it is most commonly used in implosion mode, it can also be operated in explosion mode.

FEATURES

- Fires manually

- Operates in both implosion and explosion modes

The 5000 PSI Gas Gun can be operated in implosion mode on wells with a casing pressure greater than 200 PSI. The 1/2″ ball valve is rapidly opened (180-degree rotation) to release gas from the well into the volume chamber. This action generates a rarefaction (negative) pressure pulse. A compressed gas source is not needed in the implosion mode

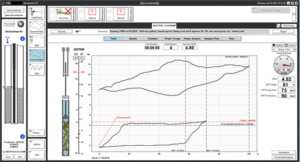

A Dynamometer is a diagnostic device used on Sucker Rod Pumped Wells that measures the load on the Polished Rod and plots this load in relation to the polished rod position as the pumping unit moves through each stroke cycle

The Well Analyzer is used with dynamometer load cells to gather dynamometer data which is processed and analyzed to determine the loading and performance of the surface unit, rod string, and downhole pump.

Two dynamometer load cells are available. The polished rod transducer is attached to the polished rod below the carrier bar. Generally, the pumping unit can be operated during the installation of the polished rod transducer. The horseshoe transducer is a very accurate load cell for performing a more complete dynamometer analysis including precise measurement of valve loads and mechanical torque analysis.

Traveling and standing valve tests can be performed. The horseshoe transducer can be used to obtain a mechanical torque analysis on the gearbox. A permissible load diagram is displayed. Motor current is acquired and displayed for the determination of motor loading and gearbox balancing

Horseshoe (or Donut) Load Cell Dynamometer:

The 4” horseshoe dynamometer transducer accurately measures polished rod load using 12 strain gauges, mounted on three supporting members. Offloading or side loading due to the carrier bar being tilted does not affect the accuracy of the load measurement.

Features

- Installed between pumping unit carrier bar and permanently polished rod clamp.

- Accurately measures polished rod load and position.

- Does not require routine maintenance.

- For use with the Well Analyzer.

- Data from the device processed by Well Analyzer software TWM.

Specifications

- Includes a built-in accelerometer

- 1.5” throat

- Rated to 30,000 lbs

These load cells are placed between the Polished Rod Clamp and the Bridle—which requires the rod string first be stacked out on the wellhead to create separation for the dynamometer to be inserted (as shown in the image where the stack-off “suitcase” is resting on the stuffing box to support the rod load)

PRT (Polished Rod Transducer) Dyno:

A popular and versatile transducer that gathers accurate

data with minimal effort. The data gathered by the device

allows for the software analysis of polished rod power

requirements, pumping unit beam loadings, rod loadings,

pump power requirements and pump performance.

Features

- Measures polished rod load and position with accuracy.

- Easily and safely installed in less than one minute.

- Position of the plunger in the pump barrel is unchanged,

generating more accurate well-performance data.

- Works with the Echometer Well Analyzer.

- Contains Load measuring sensitive semi-conductor

strain gauges.

• Accurate accelerometer

• Line pressure empty

• Flaring facilities empty